Quality management

The Olsberg quality management system based on DIN EN ISO 9001:2015 forms an active control loop. An important cornerstone is that the quality goals set by the management are made possible by providing resources and that the achievement is permanently monitored via reviews.

These include:

- identifying and translating customer expectations into successful product and service concepts, even under increasing international competitive pressure.v

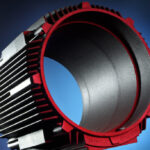

- the use of future-oriented manufacturing technologies and environmentally friendly materials.

- the flawless functional and further processing capability of our products.

In order to constantly maintain a continuous improvement process, the holistically oriented quality management system of Olsberg GmbH includes a future-proof personnel policy, which focuses on the qualification of the employees as an essential competitive factor.

Product realization begins with the determination of product-related customer requirements. Starting, if possible, with technical consultation in the design phase with the customer, as well as ensuring that all valid technical and legal regulations are available before the start of production, this ensures process reliability in production from the first test casts.

The aim here is to organize daily processes in such a way that customers' expectations are met at all times. This also includes the approach to procurement.

All products that influence the quality of the products are procured exclusively from qualified suppliers. Delivery specifications, quality agreements and incoming goods inspections ensure consistent quality of the supplier parts.

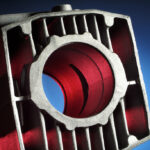

The manufacturing parameters in the production process are subject to a continuous control cycle in which data are recorded, evaluated and counteracted. To monitor and measure the fulfillment of the product's quality requirements, intermediate and final tests are carried out in accordance with the specifications.

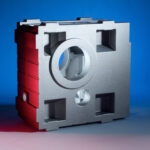

From chemical analysis to the physical properties of the materials and ultrasonic testing, the values determined are recorded, evaluated and documented in databases. Using a Faro measuring arm, the geometry of the castings is compared with the drawing specifications or the 3D data of our customers in the initial sample phase.

Even complicated geometries can be measured reproducibly. Detailed defect management enables a part-specific defect analysis with regard to internal defects as well as customer complaints.

Any deviations identified are analyzed and evaluated so that appropriate remedial and improvement measures can be initiated. This closes the circle of customer specifications and management targets via a continuous improvement process to customer satisfaction for our customers.